—Proyecto

Transportador de Cabeza de Motor Fuera de Horno

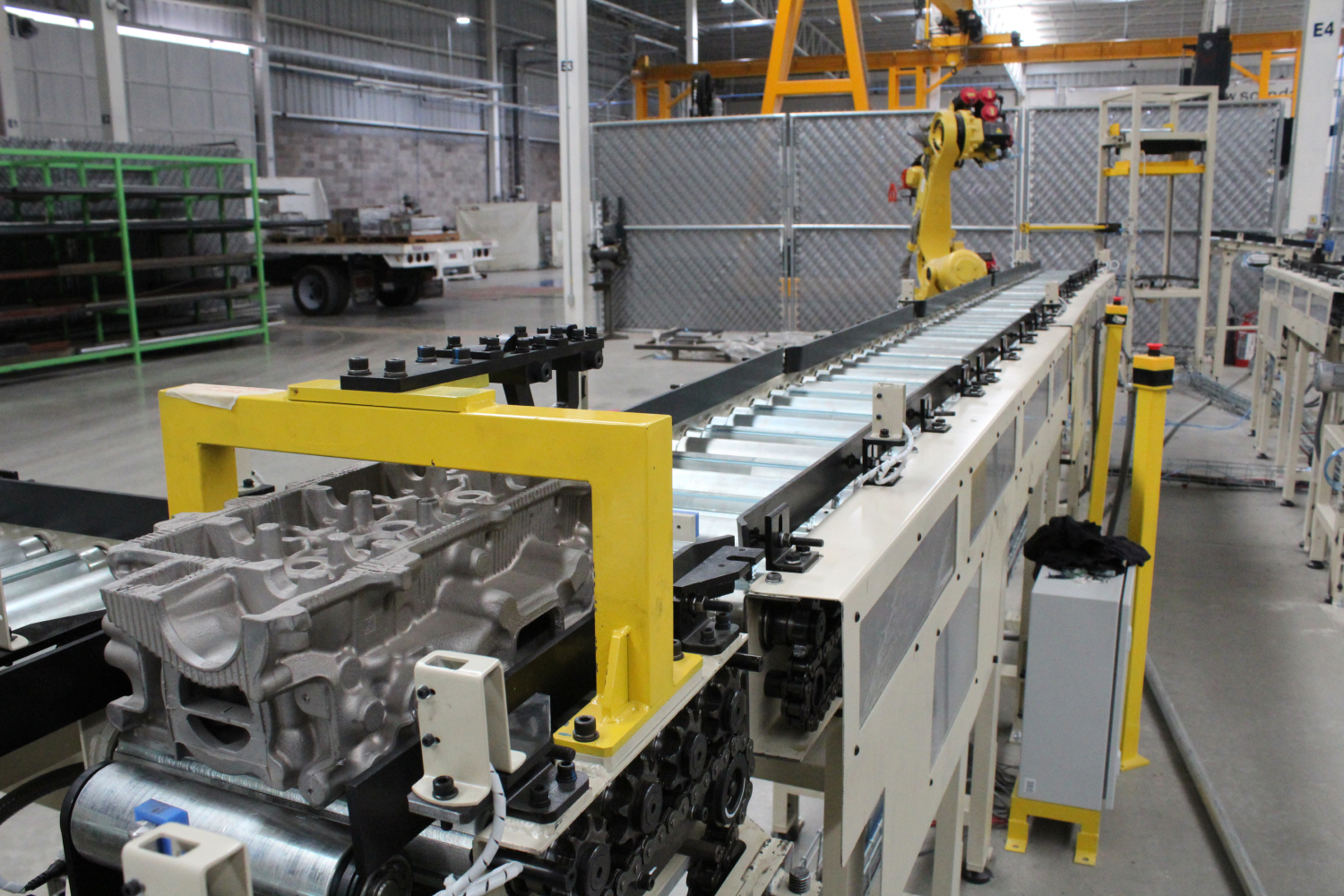

El equipo de Solinda se encargó de la fabricación de este sistema de conveyors para uno de nuestros clientes canadiense.

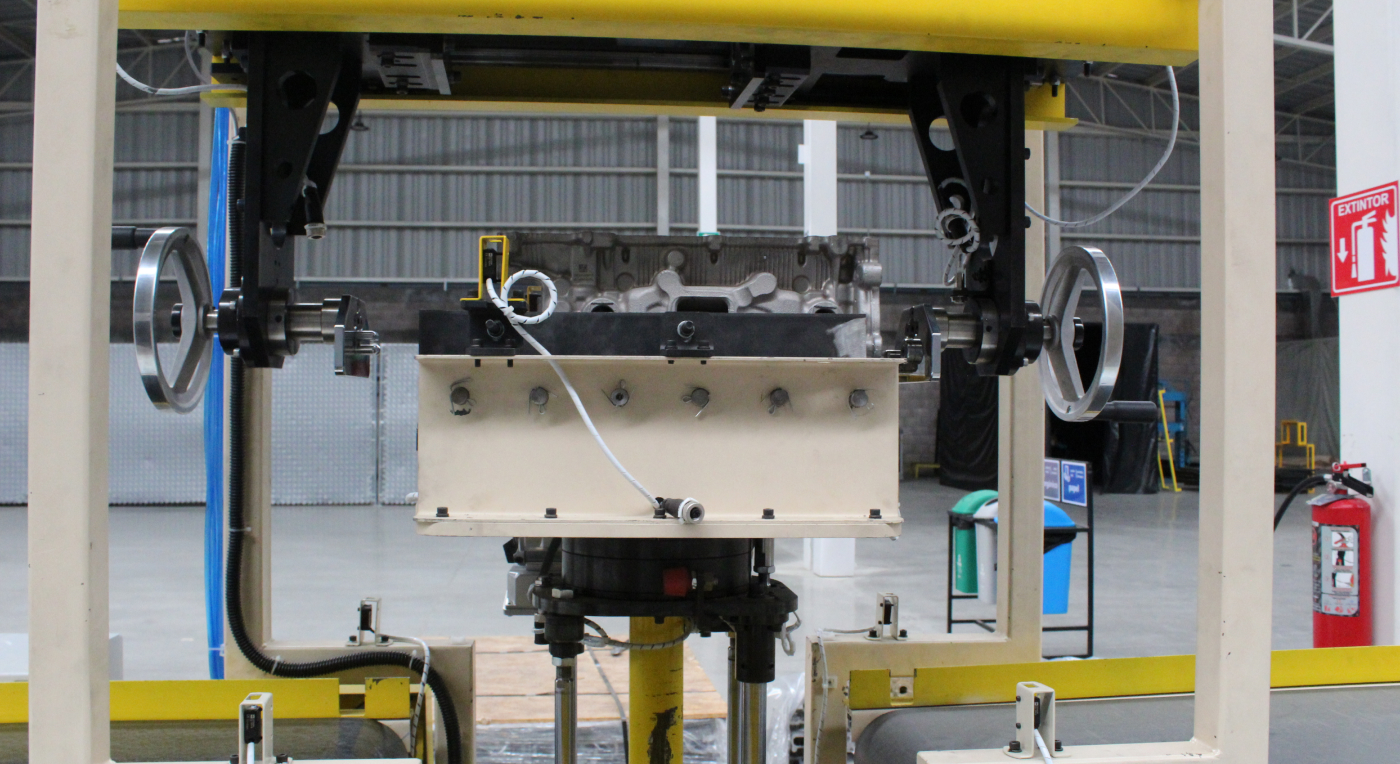

Conveyor de entrada: tiene una medida de 2 mts de largo x 7 metros de ancho x 0.75 mts de alto, con estructura de PTR y/o canal de 3” con ajuste a medidas comerciales nacionales. Para la nivelación del sistema fueron utilizados espárragos de ¾ con plato giratorio de ajuste; además, para la nivelación y el ajuste de ángulo en las patas del conveyor fueron incorporados rodillos de tracción por medio de sprocket marca Makitech, modelo KR484010s-350w, seleccionado a consideración de tiempo y costo. La fuerza es transmitida desde motores marca Sumitomo y cadena tipo Tsubaki. La estación de localización incorpora cilindros marca SMC modelo MGPM32 y sistema de elevación con cilindro SMC mod CDNA2F40, controlados por electroválvulas SMC mod VQC. Como medida de seguridad, incorpora una guarda de lámina calibre 12 en zona de carga y guardas en las zonas bajas para evitar atrapamiento.

Buffer estático: de 2.2 mts de largo x 0.9 mts de ancho x 0.82 metros de alto, con estructura de PTR y/o canal de 3” con ajuste a medidas comerciales nacionales. Para la nivelación fueron incorporados espárragos de ¾ con plato giratorio de ajuste, nivelación y ajuste de ángulo en patas de conveyor, se integran 10 nidos de localización en acero 1018 pavonados con pines de localización con cromo duro para colocación de la pieza.

Conveyor de Salida OK: de 2.18 mts de largo x .5 mts de ancho x 1.5 mts de alto, con estructura de PTR y/o canal de 3” y con ajuste a medidas comerciales nacionales. Para la nivelación fueron utilizados espárragos de ¾ con plato giratorio de ajuste, nivelación y ajuste de ángulo en patas de conveyor, se integraron rodillos de tracción por medio de sprocket marca Makitech modelo KR484010s-350w, seleccionados a consideración de tiempo y costo. Fuerza transmitida desde motores marca Sumitomo y cadena tipo TSUBAKI. Como medida de seguridad, incluye una guarda de lámina calibre 12 en zona de carga.

Conveyor NG: de 2 mts de largo x 0.5 mts de ancho x 1.5 mts de alto, con estructura de PTR y/o canal de 3” con ajuste a medidas comerciales nacionales. Para la nivelación fueron incorporados espárragos de ¾ con plato giratorio de ajuste, para nivelación y ajuste de ángulo en patas de conveyor fueron integrados rodillos locos. Este conveyor emplea gravedad para su funcionamiento, y por ende, no fue incorporado ningún elemento eléctrico o neumático.

Conveyor Retry: de 1.37 mts de largo x 0.47 mts de ancho x 1 m de alto, con estructura de PTR y/o canal de 3” y con ajuste a medidas comerciales nacionales. Para la nivelación fueron utilizados espárragos de ¾ con plato giratorio de ajuste, para nivelación y ajuste de ángulo en patas de conveyor, integra un sistema tipo cajón por seguridad, movimiento sobre guías y carros lineales marca THK . Además, incorpora un sistema activado por medio de cilindro neumático SMC modelo MK2TB63, así como sensores de detección marca OMRON, y por último, electroválvulas y manifold de la marca SMC modelo VQ7.